LinePulse: predictive

quality analytics

Leverage manufacturing data to gain critical quality insights in real time.

The Industry 4.0 solution to quality

LinePulse uses Industry 4.0 technology like artificial intelligence, machine learning, cloud computing, and advanced data analysis to give manufacturers insight into their processes and the factors that affect quality. It goes beyond the limitations of Statistical Process Control to offer advanced analysis of your process, all in real time.

Improve quality and first time through

Reduce scrap and rework

Avoid

bottlenecks

Accelerate root cause analysis

Leverage the power of machine learning

LinePulse is a predictive quality analytics software that uses machine learning to analyze manufacturing and test data from the shop floor in real time. It was built for quality, process, and manufacturing engineers to use without needing a data science degree.

Now, quality engineers can start a root cause analysis investigation of a test failure with a list of likely causal factors generated in second by LinePulse.

Manufacturing engineers can get alerted when the algorithm detects that process conditions predict an upcoming failure.

Managers can instantly generate capability reports and dive deeply into the data to optimize their process.

“LinePulse is an important solution in Dana’s digital strategy and helps our manufacturing teams automate overhead, monitor and manage product quality, and optimize productivity. Due to the success of a multi-year engagement with Acerta, we are deploying the next generation of LinePulse in key driveline and e-Propulsion plants.”

Joel Scott, Vice President, Global Continuous Improvement

Dana

Book a LinePulse software demo

Enter your contact details to open the calendar to schedule your LinePulse demo easily.

How is predictive quality analytics different?

LinePulse is an entirely new solution that doesn’t fit in previous categories of software used to solve quality problems.

- It's not SPC—predictive quality adds powerful machine learning and connects all quality data

- It's not a one-off machine learning model—LinePulse can be used to solve many different problems

- It's not an MES—LinePulse is built to go much deeper into analyzing quality data

- It's not a generic analytics tool—LinePulse ingests data in real time and provides manufacturing-specific insights

- It's not a QMS—LinePulse is designed to be used during production to analyze machine signal data

Simplify quality with predictive quality analytics

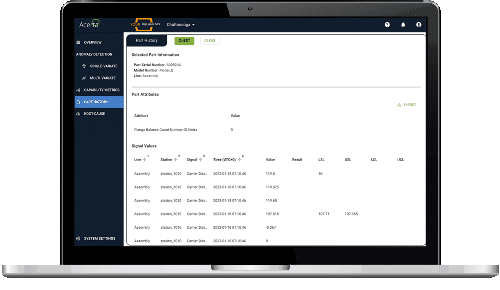

1. Ingest your shop-floor quality data

- Use our interactive view to set up your data ingestion quickly

- Ingest data from multiple sources like machine signals, test results, or product attributes

- Label data fields, and configure your station, signal, and limit data to help the algorithms understand how your data is related

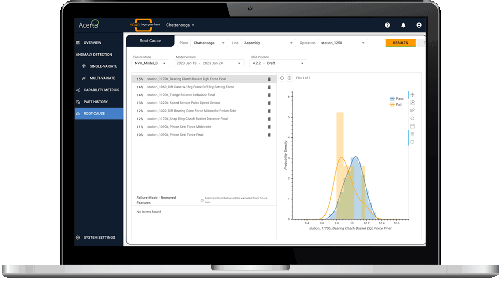

2. Automate root cause analysis

- After setup, updated data is always available for analysis

- When a unit fails a test, machine learning algorithms instantly show you the signals most likely to have contributed to the failure

- Starting with a prioritized list reduces time spent on root cause investigations drastically

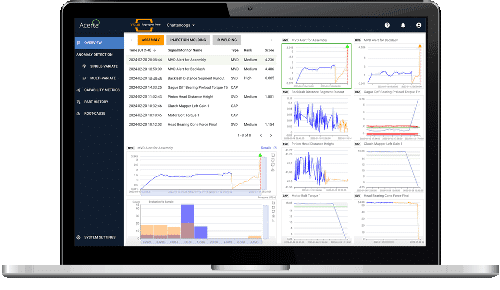

3. Predict quality issues before they happen

- LinePulse is always monitoring your data for anomalies (aka early indicators of test failures)

- Monitor specific machine signals, or add multiple signals to one group to understand how they relate

- Set up alert thresholds to customize when you get notified

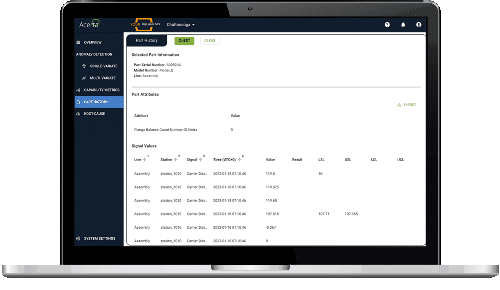

4. Generate reports and dive deeper into your data

- Generate capability metrics reports and filter by time period, model or part numbers, and result

- Drill down to view the data history for a single unit’s production

- View analysis from multiple lines and facilities from a single platform

Book a LinePulse demo

Enter your contact details to open the calendar where you can schedule your demo easily.

Predictive quality analytics in action

LinePulse FAQ

Here are some answers to the questions we often hear about LinePulse and predictive quality.

SPC is great for analyzing processes with known, fixed control limits in isolation. It wasn’t designed to analyze data from multiple sources, or explain why a failure occurred. It’s also not great at catching random anomalies and it won’t catch all defects.

The predictive quality analytics used in LinePulse provides additional value over SPC. LinePulse collects data from multiple sources and systems across the manufacturing plant and provides a consolidated view of manufacturing data, including insights on quality that you can’t get from SPC alone.

The Capability Metrics view in LinePulse provides a traditional-looking SPC dashboard which allows manufacturing teams to streamline reporting requirements and dive into data using familiar approaches. The anomaly detection functionality can catch changes in signals or drift in sensor data where traditional SPC methods would fail. LinePulse doesn’t need to replace SPC – it leverages and supplements SPC.

Some manufacturers have data science teams that work with their manufacturing data to help solve specific production and process issues, particularly to assist with root cause analysis. These teams often use custom machine learning models to analyze and solve one-off problems.

They usually determine the causes of problems and the solutions after the issues have already occurred. Unfortunately, this method of data analysis is not scalable. A new model must be built for every new issue encountered, and it can take weeks to find a solution after a problem occurs. This is time-consuming, labour-intensive, and inefficient over the long term.

LinePulse is a scalable predictive quality analytics solution that gives manufacturers real-time visibility into production. It provides the information your team needs to act on issues immediately so you can find quality problems proactively and fix them easily.

We designed our predictive quality analytics software solution to be used by experts in manufacturing, not data scientists. The machine learning algorithms and analytics capabilities are built into LinePulse and work behind the scenes to generate insights in the platform.

You don’t need data scientists to set up or troubleshoot LinePulse. For LinePulse to make an impact in your manufacturing plant, all it needs is accurate and accessible manufacturing data. Our team can assist you in determining whether your manufacturing data sources are sufficient for the predictive quality analytics that LinePulse can provide.

Every manufacturing facility is in a different stage of quality maturity and digitization. Maybe you are collecting a lot of machine signal data but you’ve never looked at it.

Maybe some of your machines have the ability to collect data, but you aren’t even storing it anywhere.

Maybe you’re interested in learning how to collect data from legacy machine in order to leverage predictive quality analytics.

By connecting with our sales team, we can give you a good idea about whether or not you can benefit from LinPulse right now, or tell you the steps needed to get your data collection where you can reap the benefits of predictive quality.

LinePulse analyzes data in real time. It is designed it to provide a constant pulse on the overall health of a manufacturing plant or line.

We designed the platform to be used on the shop floor, and for the insights it provides to be useful to the speed of manufacturing.

We harness the massive computing power of the cloud to process large amounts of manufacturing data and use machine learning algorithms to perform predictive quality analytics on that data. Storing your data on the cloud is the safest and most efficient way to run a predictive quality analytics solution. Your data will be fully secure.

And – because LinePulse is a SaaS (Software as a Service) solution – we can push continuous improvements to you through the cloud as we add new innovations to the product and you will always have the latest version of LinePulse. Cloud connectivity also gives you the ability to share your manufacturing data between different plants, regardless of their location. The cloud has a lot to offer you, the manufacturer, and us, the predictive quality analytics company. That’s a win-win in our books.

The latest release of LinePulse is version 3.0. Read the release notes here.

If you have any questions, please don’t hesitate to reach out. Our experts would love to take you through a product demo and evaluate what LinePulse can do for you.

Do you need predictive quality analytics?

If you find yourself wasting time running around the shop with a USB stick to gather data to pull into a spreadsheet, you could use LinePulse.

Unlike generic data visualization or analysis software, LinePulse is purpose-built to help manufacturers solve their most challenging manufacturing problems. Our customers end up saving time spent on root cause analysis, capability reporting, and preparing for quality audits. Engineers and managers can finally stop firefighting one issue after another, and work proactively to manage quality.

Aren’t you curious to see what you can learn from your data with LinePulse?