Automating root cause analysis in EV motors

LinePulse can be used to automate root cause analysis in the manufacturing of complex automotive assemblies, like electric motors. Here is an example.

Predictive quality and advanced analytics projects that help manufacturers solve production problems

LinePulse can be used to automate root cause analysis in the manufacturing of complex automotive assemblies, like electric motors. Here is an example.

Optimizing the setup of a new EV component manufacturing line is critical to stay competitive and form a reputation for producing good EV parts.

Balancer stations can cause bottlenecks and inefficiencies in the manufacturing process. LinePulse can help uncover problems occurring at or affecting this station.

Nissan collaborated with Acerta to develop a failure prediction system for vehicle components. Through a combination of data sets and machine learning algorithms, a prototype was created that accurately estimates engine health and predicts the remaining driving distance until failure.

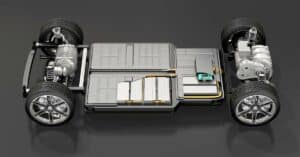

Leak testing can be a time-consuming and delicate process but it’s critical that manufacturers get it right. This use case describes how EV battery manufacturers can ensure quality with advanced analytics from their manufacturing data using LinePulse.

Injection molding requires a high degree of technical expertise to execute successfully. This manufacturing analytics use case describes how LinePulse provides advanced warning of potential defects, so operators and engineers can intervene proactively and prevent scrap.

Acerta helped a Tier-1 manufacturer to narrow down the cause of failures for axle assemblies using manufacturing data. The project reduced failure and rework rates by 65%.

LinePulse helped a Tier-1 transmission manufacturer reduce warranty claims by performing advanced analysis on complex EOL test data.

Acerta developed a machine learning model for a North American OEM to more accurately estimate friction between tires and the road surface with low excitation data.

A major European OEM enlisted Acerta to develop a machine learning model that would identify a failure in components of vehicle suspension sub-assemblies.

Acerta developed an Advanced Anomaly Detection module for a Tier-1 engine supplier to identify the causes of engine failures with 93% accuracy.

Acerta helped a Tier-1 manufacturer improve end-of-line testing for electric power steering systems.

© 2024 Acerta Analytics Solutions, Inc.

To provide the best experiences, we and our partners use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us and our partners to process personal data such as browsing behavior or unique IDs on this site and show (non-) personalized ads. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Click below to consent to the above or make granular choices. Your choices will be applied to this site only. You can change your settings at any time, including withdrawing your consent, by using the toggles on the Cookie Policy, or by clicking on the manage consent button at the bottom of the screen.

To provide the best experience, we use technologies like cookies to store and/or access device info. Consenting allows processing of data like browsing behavior or unique IDs.