Custom machine learning for manufacturing:

Acerta Professional Services

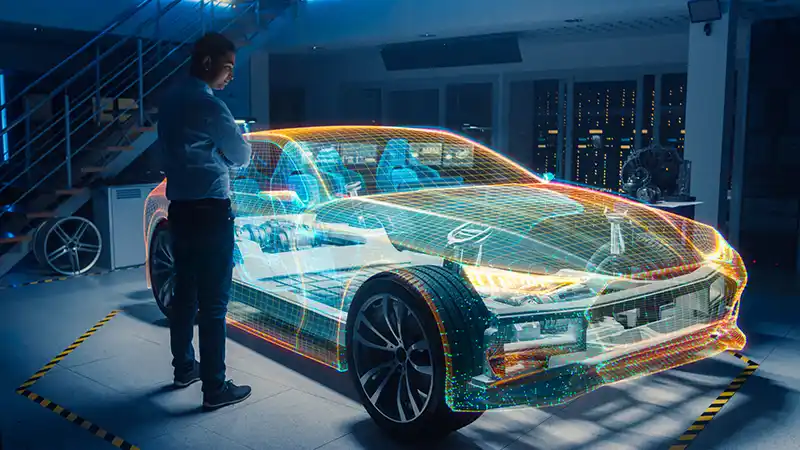

We can solve your unique manufacturing challenges with your data and our machine learning models

Do you have a manufacturing problem you’re not sure how to solve?

Most of our customers use our predictive quality analytics software solution, LinePulse, to improve part quality, reduce scrap and rework, and remove production bottlenecks. However, we also have a Professional Services team that solves unique manufacturing challenges with machine learning and advanced data analytics.

When you engage with the Acerta Professional Services team, we will work with you on a customized manufacturing analytics solution to help you solve a unique problem.

We’ll deploy a machine learning model to analyze your data and recommend solutions using our domain expertise in automotive engineering, data science, and ML/AI.

Custom machine learning solutions help you:

- Gain a deeper understanding of the manufacturing data you are already generating

- Reveal hidden relationships between stations, signals, and processes in your data

- Determine process optimizations that lead to greater efficiency

- Accelerate failure (root cause) analysis

- Identify early indicators of future product failures

- Improve production KPIs in days or weeks, not months

EXAMPLE PROJECT

Predictive failure analytics with Nissan, Japan

Together with Nissan Research Center in Japan, Acerta used machine learning to develop failure prediction analytics that detect subtle anomalies in vehicle data, predict potential failures, and estimate the remaining distance the vehicle can travel before it needs to warn the driver.

“Nissan recognizes the strength in Ontario’s thriving automotive ecosystem combined with expertise in AI and manufacturing. We worked with Acerta to accelerate the development of this new technology for our vehicles to bring future tangible benefits to our customers, and we’re excited to continue our partnership.”

Kazuhiro Doi, Nissan Corporate Vice President and Alliance Global VP Research Division

How a custom machine learning project works:

1. Project discovery and manufacturing data exploration

Our experts in manufacturing analytics and data science listen to the problem you are trying to solve, and help determine whether there is enough data available to get the answers you need.

We define a Scope of Work for the project, and determine how your manufacturing data will be shared and received. Once the data is delivered, we take a first look and ask you any clarifying questions to ensure we are interpreting it correctly.

2. Machine learning model creation

Acerta’s data science team explores the manufacturing data and determines an appropriate machine learning model. We present this initial ML model to you and discuss whether the results are leading in the right direction.

3. ML model refinement

Acerta’s data science team takes your feedback and tweaks the machine learning model to take any more contextual information into account, and make it as precise and accurate as possible.

4. ML model deployment

Not every data science project includes deployment of a live model. When this is necessary, we determine the most convenient way to deploy the model for your team to use on an ongoing basis.

We deploy the model and train your team how to run it, and how to interpret the results.

5. Reporting

Final project documentation, recommendations, or reports for the project are delivered as necessary according to the Scope of Work.

If a machine learning model was deployed, an agreed-upon number of check-ins are set up on a regular basis to ensure that the ML model is working correctly, and we answer any lingering questions.

“We are thoroughly impressed with the level of expertise and dedication demonstrated by Acerta in supporting ZF to develop an AI-based road friction estimation module. Thanks to Acerta´s innovative solution, we have significantly improved our ability to predict grip conditions and ensure driver safety.”

Dr. Julian King

Research and Development Engineer