How machine learning helps manufacturers on their digital transformation (DX) journey

Last updated on October 25th, 2022

Digital transformation (DX) may seem daunting, but 95% of manufacturers agree it is essential to their future success. DX is about using new technologies to better solve traditional problems, from improving product quality to driving efficiency to increasing productivity and ensuring equipment uptime. Industry 4.0 technologies like machine learning (ML) are helping manufacturers optimize their products and processes, and this can’t come soon enough.

Precision manufacturers like automotive tier-1s are under great pressure to perform. They are turning to emerging technologies like machine learning to become faster, nimble, and more efficient, to aid in the development of innovative new products, such as parts for electric vehicles (EVs). Current supply chain disruptions are also forcing manufacturers to optimize production for the sake of improving inventory and supply issues. At a time when 94% of manufacturers have concerns about their supply chain, it’s no wonder that 91% have responded by boosting their investment in DX.

Machine Learning and the DX Journey

Most precision manufacturers know that machine learning will help drive productivity, performance, efficiency, quality, and more, but they are stalling at the starting line. While terms like machine learning and artificial intelligence (AI) are often used when people talk about digital transformation, the ultimate goal is to leverage the mountains of data that companies are collecting and generating, to improve manufacturing decisions, products, and processes.

Let’s break it down: machine learning is a form of Artificial Intelligence. ML uses algorithms or statistical models to solve problems or perform tasks, such as conducting real-time pass/fail analysis on the production line or predicting which parts will be most likely to fail. There are 3 styles of machine learning for manufacturing: supervised, unsupervised and semi-supervised.

Supervised learning models use labeled data to solve well-defined problems, such as predicting and identifying product defects based on known (labelled) failure data. Unsupervised learning, on the other hand, uses unlabelled data and allows the model to work on its own to uncover patterns in a data set, such as identifying trends and issues across the entire supply chain or interpreting historical and current sensor data to predict (and avert) machine downtime. A combination of the two, semi-supervised learning uses both labelled and unlabelled data to train the models, such as using tested (labelled) parts data and comparing it to untested (unlabelled) parts data to predict which untested parts will fail.

Since labelling data is a huge undertaking, manufacturers work most frequently with unlabelled or partially labelled data. Overall, the style of machine learning used depends on the type of data and the problem at-hand, so a manufacturer may use a combination of styles across production lines and factories.

Providing Insights Based on a Single Source of Truth

Machine learning is always learning. Leveraging Internet of Things (IoT) sensors and technologies, plus current and historical data, ML has the power to predict, recommend, and provide insights to help manufacturers make highly informed, data-driven decisions. Putting an end to siloed manufacturing data that is often isolated by division, the best ML solutions collect and compile all the data into one place – a single source of truth – to solve manufacturers’ problems. This single, trusted data source can inform all stakeholders, from executives to plant managers to engineers to technicians, providing insights that drive operational improvements and optimize product quality and output.

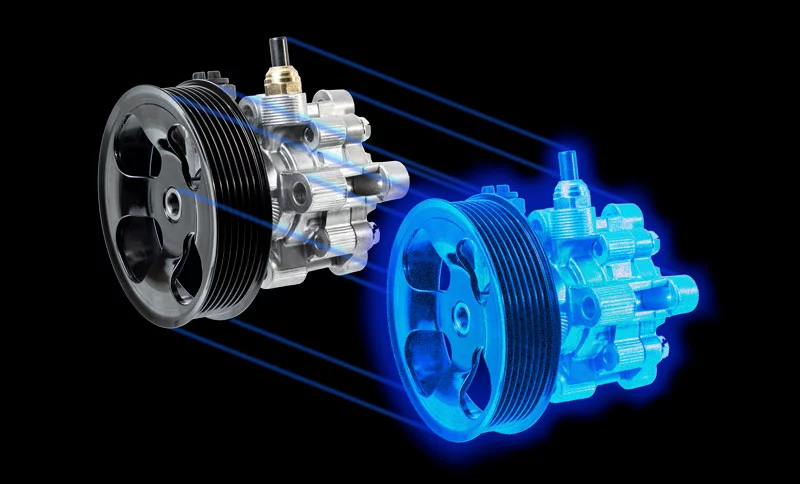

Pulling data from a single source of truth, ML can also help stakeholders gain visual insights, which can further aid in decision-making. For example, the data can be used to create a digital twin, a real-time digital model simulation of the entire production process or parts specifications. A digital twin can illustrate how each step in the process is affecting each component, as well as how to increase throughput and product quality by manipulating the component or process. Since ML technology is predictive, digital twins can identify early problem indicators and suggest ways to fix and avoid problems proactively.

Ready to Move Forward?

With most IT departments already working at capacity, moving forward with the DX journey can be complicated, but it’s well worth it. And, there are IT solutions and service providers that can assist. Companies like Acerta bring the strategic knowledge and tactical tools to help companies like yours adopt and benefit from ML technologies. Our LinePulse solution can eliminate the time, cost, and complexity of one-off ML models, provide a digital view of your production, display timely manufacturing floor information at-a-glance, and evolve as your manufacturing line changes.

If you’re ready to extract actionable insights from your data, get in touch.

Share on social: