A digital twin provides a virtual replica of your parts and production line

Last updated on October 24th, 2022

One of the most important lessons learned from the Third Industrial Revolution (Industry 3.0) is that data on its own is worthless – unless it can be used to produce results. That’s where Industry 4.0 comes in. While Industry 3.0 enabled automated and networked production, this fourth industrial revolution ushered in cyber-physical systems that leverage machine learning (ML), artificial intelligence (AI), and Industrial IoT (IIoT) sensors to collect, digest, analyze, and use data to optimize production.

These technologies can also be employed to create digital twins, or virtual models. ML/AI technologies – combined with IIoT sensors and advanced analytics – can enable precision manufacturers to create virtual models of real-world production lines and components, to ultimately improve product throughput and quality.

The two main categories of these virtual models are high-fidelity digital twins and low-fidelity digital twins, each having their own unique features and benefits.

High-Fidelity Digital Twins

During Industry 3.0, there were no standard protocols for data collection from independent stations or sensors along a production line. In Industry 4.0, IIoT technologies have taken data utilization to the next level. Information collected from independent machines and sensors can now be accumulated in one centralized location, where it can be manipulated to create a static, simulated representation of a component – also known as a high-fidelity digital twin.

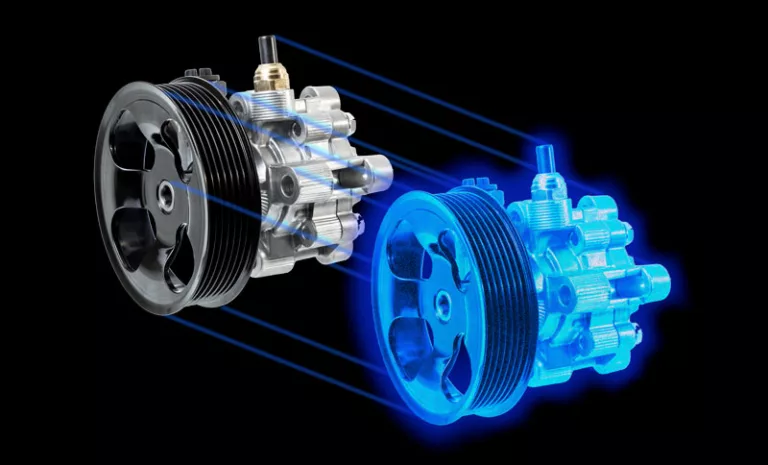

A high-fidelity digital twin is a virtual model based on the fixed physical specifications of a particular object or system. The simulation is usually created using CAD data and kinetic design files to generate a 3D model of a part or procedure, which can be animated, making it easier to interact with. For example, an automotive engineer can observe a precise virtual 3D twin of a car’s front disk assembly and manipulate the twin to see the assembly from all angles.

High-fidelity digital twins are not commonly used in today’s IIoT landscape because of the prohibitive costs associated with 3D renderings. Additionally, they are often copied from proprietary designs which are protected by intellectual property rights. In some cases, the designs are available but legal costs and copyright hurdles can make them unattractive. However, the most significant reason why high-fidelity digital twins are not more widely used is that they only capture the static features of the object or system and not their dynamic workings.

Since high-fidelity digital twins cannot display the operational status of a part or process, precision manufacturers tend to use low-fidelity digital twins instead, as they clearly illustrate how a component or system is actually performing.

Low-Fidelity Digital Twins

When Industry 4.0 bridged the gap between the static and dynamic data collected from the production line and introduced IIoT sensors and ML/AI systems, it also paved the way for the creation of low-fidelity digital twins. These digital twins are produced by capturing operational steps and real-time object specifications from the production line to generate digital model simulations.

A low-fidelity digital twin can provide a holistic, digital view of the entire production process and the physical parts being produced, to deliver dynamic, real-time operational status and product data updates. Precision manufacturers can use this information to determine what effect each process is having on any particular part in real time, and how they can then manipulate the component or process to increase throughput and improve product quality.

The predictive capabilities of the technology used in low-fidelity digital twins can be utilized to detect anomalies in a component’s design and suggest the best course of action to avoid problems and make improvements. Precision manufacturers can also use the twin to identify areas where they can increase the efficiency and life expectancy of their production line and manufacturing equipment.

Ready for Your Digital Twin?

Acerta’s proven ML/AI solution, LinePulse, can measure and monitor independent streams of data from multiple sensors. By aggregating and analyzing all the relevant data from all sources, it can deliver a digital twin of your manufacturing line, which is custom to your needs. These digital models can provide valuable, virtual insights to your engineers, enabling them to develop data-driven action plans that increase efficiency, flag where to look for failures, avoid problems proactively, and solve issues faster.

Want to learn more? Get in touch.

Share on social: