Uncovering data-driven optimizations for precision manufacturers

Last updated on October 25th, 2022

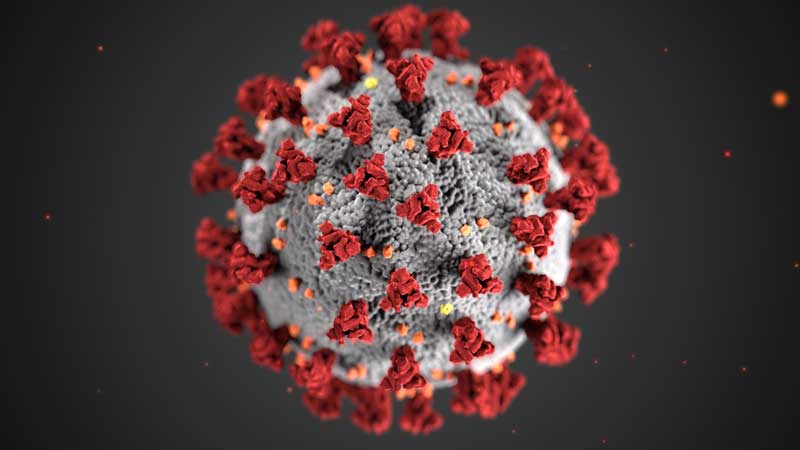

The pandemic has caused entire industries to rethink how they do things. While shutdowns and supply chain issues have caused major disruptions for automotive and other precision manufacturers, they also brought a huge surge in demand. And to meet this demand, modern and innovative production models are needed. Manufacturers need to embrace new digital capabilities and continue (or begin) to invest in Industry 4.0 initiatives.

What is Industry 4.0?

It’s a term commonly used to describe the 4th industrial revolution. Whereas the first industrial revolution was driven by steam power and mechanization, the 2nd by electricity and mass production, the 3rd by computers and automation, this 4th industrial revolution, Industry 4.0, is driven by data and advanced technologies. These technologies include cyber-physical systems, like the Internet of things (IOT), cloud computing, virtual and augmented reality, artificial intelligence (AI), and machine learning (ML).

How does Industry 4.0 apply to precision manufacturing?

While Industry 4.0 is associated with some really cool technologies, data is what really drives it. Industry 4.0 means the massive amount of data you’re collecting can be analyzed to identify patterns and actionable insights faster than ever before.

Precision manufacturers, such as those that produce automotive and off-highway vehicles, can leverage these insights to improve products, optimize operations, and troubleshoot issues in real time. In fact, everything, from supply chain to prototype to production to diagnostics to distribution, will progress in a future of connected systems that proactively leverage insights from data – learning and making adjustments along the way.

Uncovering data-driven optimizations

Unlike with purely human-powered analytics, massive amounts of data points can be continuously analyzed across product lines and facilities using ML/AI capabilities. It’s all about leveraging the data before, during, and after production to gain insights into product quality or predictions about future product fails, such as faulty transmissions or suspension failures. Such data-driven knowledge can enable precision manufacturers to:

- Improve throughput and quality while reducing rework and scrap

- Monitor for abnormalities and see how the data has changed over time

- Locate and analyze the root causes of defects with greater accuracy

- Resolve problems proactively and eliminate disruptive impacts on production

- Gain a real-time view of production and quality from anywhere in the world

- Reduce or do away with repetitive data processing and analytics tasks

- Save costs through data-driven optimizations

Manufacturing equipment can also be optimized using data from the production line to anticipate equipment failure and enable intervention in time to repair or replace it, avoiding lengthy downtime. As with predictive analytics, such predictive maintenance also relies on analyzing mountains of data, making AI/ML the new essential manufacturing tool. Plus, with the machines doing the monotonous tasks, like monitoring, data processing, and analytics, your team will be freed up to focus on the big picture, like developing data-driven action plans.

A wait-and-see approach won’t work

Deloitte notes that, “More organizations are making progress and seeing results from more connected, reliable, efficient, and predictive processes at the plant.” But first you need to embrace what manufacturing is becoming. While the pandemic has caused a slowdown on Industry 4.0 initiatives for some companies, the most successful ones are steaming ahead.

In fact, Industry Week named COVID-19 the 2021 Manufacturing Technology Leader of the Year, due to the game-changing impact the pandemic has had on the rate of investment in digital technology. COVID-19 didn’t just make digital transformation a should-have, it made it a must-have. While the pandemic and its continued impact on families, communities, and businesses is tragic, it has also taught industry to approach problems differently, breathing new life into manufacturing practices and processes.

It won’t take long to see ROI. BDO’s 2021 Industry 4.0 Survey showed a bullish 50% of manufacturers believe their digital investments will lead to revenue increases within 12 months. The survey also showed that Industry 4.0 adopters are more resilient, agile, and connected than less-advanced legacy manufacturers. It’s all about connectivity and leveraging real-time data to do better and be better. By merging insights gained by machine learning with the production line, precision manufacturers can solve and prevent issues, and they can also increase throughput rates, reduce rework rates, and optimize product quality.

Ready to get started?

Acerta helps precision manufacturers turn complex product data into actionable insights that improve the manufacturing line and the bottom line. Want to learn more? Get in touch.

Share on social: