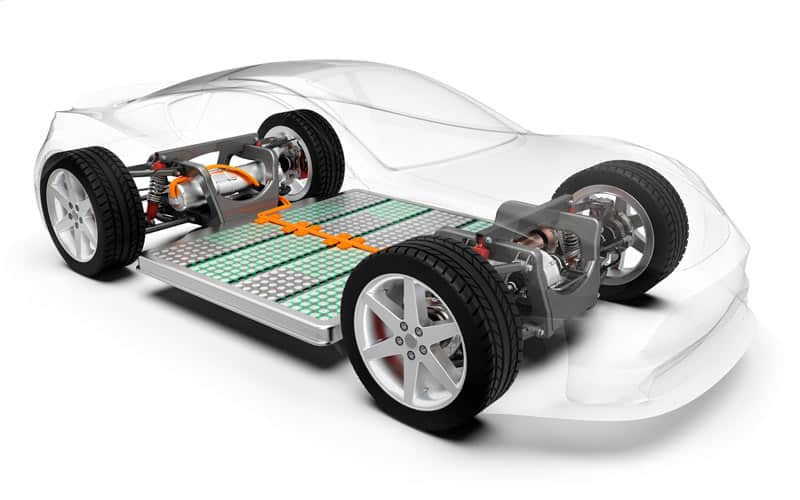

LinePulse analyzes product and production data generated during precision manufacturing of parts for electric vehicles and those with IC engines. It combines traditional analysis with machine learning and AI (ML/AI) models for advanced analysis in real time, to empower operators and engineers to prevent and solve quality issues before they impact production.

Manufacturers need to develop better, more efficient EV components, understand how new part designs will impact production, and ensure quality while introducing new products to market as quickly as possible. Real-time data empowers you to innovate and iterate, and reduces the need for additional tests.

Enter your contact details to open the calendar where you can schedule your demo easily.

Simplify quality with LinePulse

© 2024 Acerta Analytics Solutions, Inc.

To provide the best experiences, we and our partners use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us and our partners to process personal data such as browsing behavior or unique IDs on this site and show (non-) personalized ads. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Click below to consent to the above or make granular choices. Your choices will be applied to this site only. You can change your settings at any time, including withdrawing your consent, by using the toggles on the Cookie Policy, or by clicking on the manage consent button at the bottom of the screen.

To provide the best experience, we use technologies like cookies to store and/or access device info. Consenting allows processing of data like browsing behavior or unique IDs.