Last updated on March 14th, 2023

Case Study

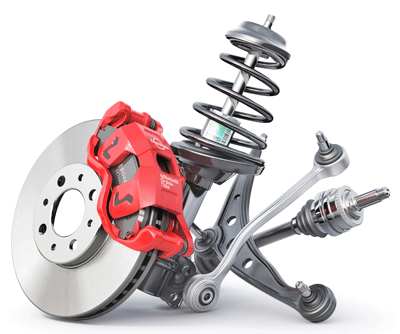

Predicting suspension failure with machine learning

Objectives

- Use machine learning (ML) models to predict failure in suspension components

- Improve vehicle reliability and safety, while reducing cost of maintenance

Challenge

- Correctly identify specific failures and failure modes in select components

- Use only 2 engineered features and 2 vehicle data signals to build ML models

Key Results

Models can be easily adapted to production vehicles

Timely alerts for drivers provided and better data for service technicians

Background

While some automotive OEMs use machine learning and artificial intelligence (ML/AI) in their manufacturing processes, many are now moving towards using data analytics with predictive analysis to enhance the driver experience. The goal is to improve everything from vehicle reliability and safety to reducing the cost and complexity of vehicle maintenance.

A major European OEM wanted to significantly expand its current service model by applying ML/AI predictive analytics to vehicle Controller Area Network (CAN) bus data, using new developments in 5G communication, cloud, and other technologies to leverage this expansion. They enlisted the help of Acerta Professional Services to develop custom, unsupervised ML models that could correctly identify a specific failure and failure modes in select components within the vehicle suspension sub-assembly.

The Problem

As part of this new service model, the OEM wanted to add suspension predictive maintenance alarms to vehicle dashboards, so drivers would be notified and prompted to visit a service center before critical suspension components failed. This would give timely warning to drivers and indicate to service technicians if wear or corrosion caused the failure.

Solution Process

Utilizing time-series vehicle bus data provided by the OEM, combined with Acerta’s internal engineering knowledge of mechanical failure and how it manifests itself in data, Acerta applied ML algorithms and data science to develop predictive models. These models would identify failures and actively ignore variability from driving styles, road conditions, and other unwanted environmental inputs.

As an additional challenge, the OEM requested that Acerta use only two engineered features, and just two vehicle data signals to avoid excessive bandwidth during data transfer. Acerta developed two separate models — a classifier and a regression model — to ensure soundness of results and predictions. Both models had similar performance results when tested on unmarked data: 75% and 70% respectively.

Results

The Acerta Professional Services team provided value in two ways to this OEM. First, Acerta proved that the data collected from test vehicles had value and could be used to develop predictive models.

Second, by reducing model reliance on vehicle signals and large data transfer bandwidth, Acerta demonstrated that the same models could be easily adapted to production vehicles. End users will have safer vehicles and better peace of mind.