Why automakers should focus less on OEE and more on part quality

Last updated on July 24th, 2023

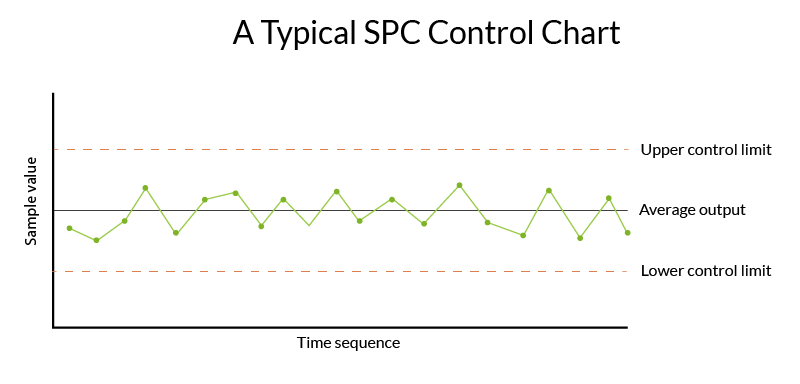

Quality management in manufacturing is often looked at through the lens of process optimization, partially due to the long-standing dominance of statistical process control (SPC) as a solution for quality. SPC was developed in the 1920s and has remained an automotive industry standard for manufacturing quality control ever since.

The concept of SPC rests on the assumption that a perfect process with highly-functioning machines will produce the highest level of quality possible. But, SPC has some gaps. Control charts display the measurements of each isolated signal and the actual outcome of processes, i.e., the final quality of the part, is not considered.

There are other calculations that can be used to measure the quality of a manufacturing process. OEE or “Overall Equipment Effectiveness” is a calculation for measuring manufacturing productivity. OEE is calculated with the formula (Availability)*(Performance)*(Quality).

With quality factored into the equation, this metric provides an opportunity to measure quality fluctuations over time. However, OEE does not complete the quality picture. OEE can’t tell us why defects are occurring. It is still based on a process view of production, where the speed and uptime of the operation is the focus, and quality has no context. There isn’t much we can learn from this equation about how to make better and higher-quality parts.

In automotive manufacturing, what does a part quality approach look like?

A part quality approach looks at each part being built, all the sub-components that form it, and all the actions that impact it by tracking it through the manufacturing process with a unique serial number. Then, data patterns can be analyzed to look for patterns or correlations and variations in production. The outcome of the entire production process and the output is considered, not just the health of the machines and mechanisms creating it.

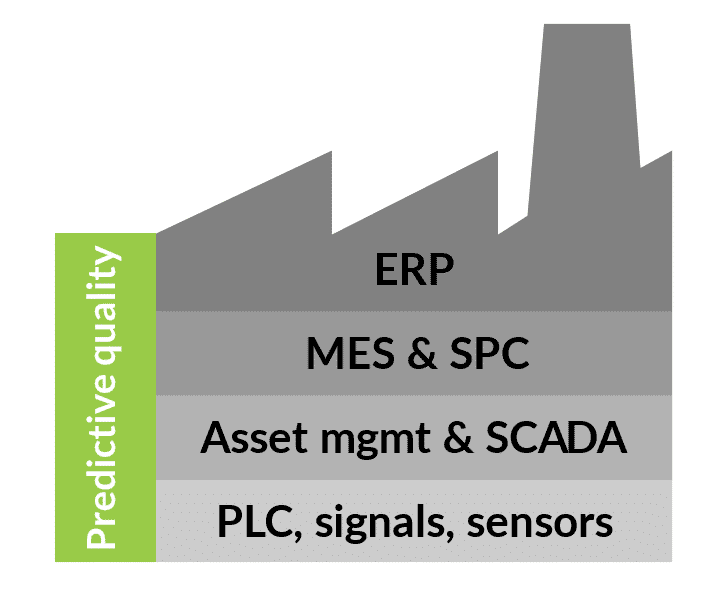

The typical manufacturing tech stack starts at the PLC or sensor level, with asset management tools and SCADA built upon that. SPC solutions and manufacturing execution systems are used for operations management and statistical analysis, with ERP systems at the top of the pyramid.

We propose that a predictive analytics software solution should integrate with these systems in order to truly understand the causes of defective parts during production.

The updated tech stack we propose looks something like this:

Solving part quality problems with a predictive quality analytics solution

There are solutions on the market that use advanced analytics to solve process quality problems on the line. Many of these are built for continuous or process-based manufacturing. These tools work well in industries like Food and Beverage, where problems are often based on overall quality and reducing scrap rates. But these tools are not ideal for manufacturing expensive precision parts, like the precision parts built for automotive, off-highway, and electric vehicles.

With more expensive, complex parts such as transmissions, electric batteries, and engines, it isn’t enough to look at quality from a process perspective. Scrapping even a handful of high-demand parts like electric batteries after production is a huge opportunity cost. Since these parts have serial numbers, they are perfect candidates for a predictive quality solution to monitor their production. Predictive quality tools can closely monitor multiple data points in real time to alert operators before a defect may occur, and allow deeper analysis into the root causes of problems – so quality issues can be identified and solved quickly and accurately.

Many automotive manufacturers understand the difference between optimizing their processes and looking at part quality specifically, but they have not yet adopted tools that support higher part quality during manufacturing. They may simply be unaware of the improvements that these tools can add.

Some manufacturers might argue that the cost of tolerating certain defects is a cheaper and safer option than upgrading machinery or changing their approach to quality. If manufacturers can accept a certain percentage of defects and stay profitable, do they really need to add a part quality solution? For some facilities, the answer may be no or not now but the automotive industry is changing rapidly and those who take a long-term view of success will definitely find value in improving part quality.

Changes in the automotive industry require a look at part quality

Global supply chain disruptions

Global supply chain disruptions continue to slow the movement of raw materials and parts. The cost of fuel has driven some raw materials up in price, which means that wasting these materials in the form of scrapped parts has a more expensive price tag than ever. If tolerating a certain percentage of defects is baked into the profitability equation on a certain line, then this equation will begin to break down as the costs of materials increase and quality remains the same. Focusing on part quality is a way to ensure that the cost of materials can be minimized.

Government regulations

Regulations are tightening around automakers to meet sustainability targets and increase consumer safety, which also shift the types of vehicles they are producing and how they are made. Regulations may imposed on a national or international level. And, sustainability regulations are becoming more stringent. especially as the impacts of climate change are being more noticeable on our environment.

Adhering to these limitations requires agility from manufacturers. By implementing a part quality solution to achieve better insights into production and part quality, manufacturers can more easily adhere to narrowing specification limits for the parts they produce.

Increased competition and innovation

There is an increase in competition in the automotive manufacturing market. Consumer demand is shifting towards technologically advanced and connected vehicles and EVs. Automotive manufacturers must be able to produce high quality parts based on new and emerging designs and with new techniques.

With the speed at which innovation of new components is happening, it is important to validate quality quickly to keep up with the market. If quality is only looked at through traditional means of process control, it will simply not be fast enough to keep up with ever-refining specifications, changing methods of production, and quality testing.

How predictive quality can benefit automotive manufacturers

Scale production more quickly

Using process improvements alone to control quality can also limit a facility’s ability to scale. Take an example of a plant that produces 10,000 cell stacks in a year. Each cell needs to go through a 2-hour end-of-line test to validate it before leaving the facility. If the production volume were to increase to 50,000 parts per year, this would cause a huge bottleneck at the testing stage. The facility would run out of physical space to house completed parts once before they could test them. Extra testing devices would need to be purchased to get through this volume, which would cost money and time to purchase and install.

If there was a predictive quality solution implemented in this facility, more complex checks and measurements using artificial intelligence and machine learning to analyze production data could reduce the end-of-line testing time needed to ensure a quality part. If that test time could be reduced to 30 minutes, then the potential to scale to the 50,000 parts per year aspiration is much more realistic and much more affordable.

Increase the pace of innovation

With new technology and EVs, innovation is happening rapidly and there is a race among part manufacturers to keep up with changes and demand. Tier 1 suppliers focusing on producing high quality, reliable parts will win and retain large contracts from cutting-edge OEMs. Exact specifications, part lifespan, standardization, and manufacturing methods for newly created parts are still in development and there are a lot of unknowns.

Manufacturers who take a predictive quality approach and are looking at granular data from their assembly line signals and end-of-line tests and are able to see patterns. This will give them the upper hand when it comes to refining specifications for parts or effectively altering their processes as requirements change.

Using a predictive quality tool allows a more transparent view into manufacturing data. This data can be shared directly with design teams, which can allow a more collaborative approach to developing new parts. The faster feedback from the shop floor and testing, the more prepared designers will be to solve downstream problems in their future product iterations.

Become a proactive partner with OEMs

Taking a close look at part quality internally also allows Tier 1 suppliers to engage more proactively in decision making with OEMs. If all else is equal but a facility is able to manufacture a part within a tighter specification range than its competitors, they may be preferred as safer option. This is especially true if those spec limits are newly developed and the part has not yet been as widely tested. There is also an opportunity for the supplier to take a more active role in the relationship with an OEM if they are able to provide helpful insights on the part’s production, testing processes, and methods for manufacturing it.

These insights can help the OEM understand the possibilities and limits of their own requirements better – and provide helpful feedback for R&D teams. All of this can translate into a highly valued working relationship, where the supplier is able to offer more overall value than a competitor who is simply dropping off parts without conversation.

Expand your customer base

A focus on part quality may also offer a supplier some additional opportunities in terms of the OEMs who are willing to purchase their parts. For example, consider a part such as an axle system that has specifications that limit the amount of noise it can create. A large vehicle will have a higher level of acceptable noise for the axle to make. But, if a supplier is able to produce this axle well within specification to become very quiet, they may also have the potential to sell this same component to other OEMs who are producing vehicles that have lower noise requirements.

Process and part quality need to work together

Despite the emphasis above on turning toward a part quality approach in manufacturing, process quality should not be abandoned nor should it take a backseat.

A part quality focused assembly line could be created to output the ideal part that has extremely high performance and meets spec every time but if the method to get there involves a long, slow and specialized production process, then the costs to produce this level of quality will not make the business viable. Continuing to value process improvements and efficiency can mean the difference between a business that is wildly successful and one that is unprofitable.

Industry 4.0 is ushering in new technology and innovation at an alarming rate that may seem overwhelming to manufacturers who must now focus their budgets on new investments that will translate to reduced costs and higher revenue. There is a tremendous amount of pressure to make the right decisions about new manufacturing tech. Tools that can directly impact the quality of parts produced, reduce scrap and rework, and reduce the risks associated with warranty costs are investments that can demonstrate ROI very quickly after implementation and for a long time thereafter.

Share on social: