How can the auto industry make ventilators?

Last updated on August 26th, 2022

The COVID-19 pandemic represents a turning point in history, and the ways in which we respond individually and collectively will fundamentally shape what comes next. In the short term, many of us are doing whatever we can to alleviate the pressures being placed on our healthcare systems and frontline workers, including ramping up production of essential medical equipment and supplies.

The automotive industry has been tasked with contributing its considerable resources to ventilator manufacturing, an endeavour that’s been met with both optimism and skepticism. In an effort to understand what’s really involved, I sat down with two of Acerta’s resident automotive experts (remotely, of course): Nathan Lai and Luke Richard.

How difficult would it be to go from making auto parts to medical equipment?

Nathan: For a ventilator—and let’s just pretend there’s no controller right now—I’m imagining some mechanical pump or valve assembly. In terms of making the components for that, Ontario probably has the supply chain to make all of the components itself already. Whether it’s machining metallic components or rubber components, valves and gaskets, we can probably make all of that, and they’re made using essentially the same equipment. If you need a bracket, that’s going to be the same process you’d use to cut a transmission housing. So, that’s the first thing.

Where it gets a little bit more challenging is in the assembly. You can retool some assembly capital to make it easier, but what I think a lot of manufacturers are probably doing is relying on manual assembly. Wherever you could get away with retooling easily, then you would, but if it’s time- or cost-intensive, doing it manually makes a lot more sense in terms of speed and efficiency.

If I had a machining plant that’s empty because I have no orders because of COVID-19 and somebody tells me, “We need to make this metallic component for ventilators,” I’d jump at the chance, since my capital’s sitting idle and all I need to do is make some ginger fixtures so my machine can make whatever needs to go into the die or the pump. Where it gets more complicated is when you have to put it all together, but a lot of the larger assembly plants are semi-manual and semi-automated anyway.

Luke: The Ford plant in Rawsonville that’s making ventilators normally does oil pumps and auxiliary components, as an example.

Nathan: Yeah, and in a case like that, they could retool a lot of the equipment to make a ventilator because a lot of it isn’t hard tooling. They’re not dedicated machines where the robot arms are fixed because the bolting position is fixed—something like that is never going to be retooled to make ventilators because that doesn’t make sense, but if we’re talking about a lift assist that’s semi-automatic, that could be retooled for a ventilator piece.

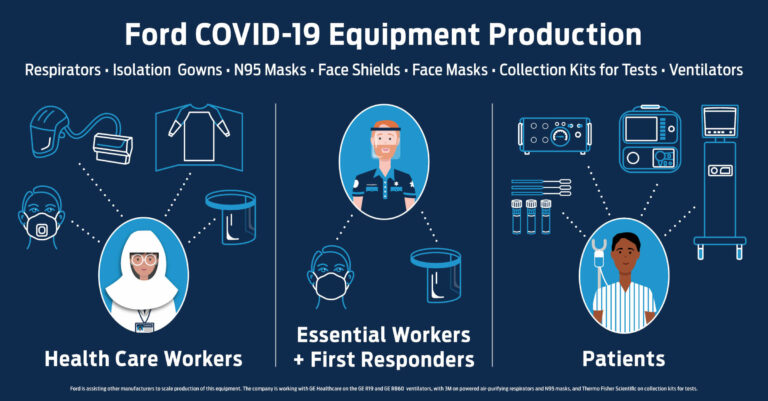

Image courtesy of Ford Motor Company.

So, the difficulties essentially come down to what’s automated versus what’s manual?

Nathan: Well, the harder part, in my opinion, is the controller. It’s not good enough to just have the mechanical portion of a ventilator. You need a controller that can respond to feedback from things like heart rate and oxygen level.

Luke: Hospitals have shop air to get pressure, so there’s a pressure regulator with a valve that turns it off and on, and it doesn’t even discharge; the lungs decompress and slowly release the air. So, it’s more like a vacuum assist.

How do you think the knowledge transfer would work? Are the medical manufacturers just sending automakers their blueprints?

Nathan: I would say that if it’s going to be an approved ventilator, then yeah, they’d be getting prints. Ford and GM aren’t going to design a ventilator or a valve in a situation like this. More likely, they’re working off of an approved design.

Luke: The other factor is that even when an automaker is ready to switch to making ventilators, where are they going to get the parts? That’s why Tesla is using their own supply chain to mitigate that risk. If we’re just taking the supply from ventilator manufacturers, we’re not actually helping them.

Image courtesy of GM Canada.

If your boss came to you and said, “Okay, we’re going to start making ventilator parts and you’re in charge of running the line,” what would be your biggest concern?

Nathan: To be honest, I would love to do that, because this is the best part of process engineering. My response would be, “Just show me the print!” Once I had that, I would start by 3D printing everything and then go through my entire line for each component and ask, “Where can I fit this piece?” I’d walk out the 3D-printed pieces and use those to figure out what kind of tooling we’d need. If we ran into any serious issues in assembly, we’d just go manual.

It sounds like it’s not as difficult to go from making an oil pump to making a “lung pump” as you might think.

Nathan: Yeah, in my opinion, making the individual components is the easiest part. The only real obstacle is cleanliness. Aside from that, as long as your facility makes the same size parts, it should be possible. What I mean by that is that if a ventilator was massive, you wouldn’t want a plant that’s used to doing small, precise assemblies. But if it’s the same size then it’s very likely that you have a lot of existing tooling or stations you could still use. Even something like a robot cell for packing; you could probably retool that to pack out ventilators.

Luke: A ventilator also costs way more money than these automotive components do, so there’s a huge margin to play with, so whatever the difficulties you’d face in building them, it’s worth the investment. We’re talking about the difference between making an oil pump, which might be $20/part, versus a ventilator, which can be $30,000.

What about the labor side of the equation? Are we talking about essentially the same skill sets?

Luke: Yeah, if they’re using similar equipment to make something different, it’s the same skills that transfer, so you could still use a general operator to put most of this stuff together. Even if you needed some specialized equipment, that stuff can be set up pretty quick.

Nathan: A lot of these plants will have dedicated automation groups, so if you tell them, “Stop everything you’re doing and make this station,” they could flash that up in three weeks, as long as they had the equipment. Most of these manufacturers, even on a steady state line, there’s a lot of stuff that happens very quickly and very nimbly. So, this whole idea of, “You need to put this together now. How do you do that?” That’s what these people do.

Luke: If you take a look at the Tesla video [see below], you can see that the controller is probably the most complicated part.

Nathan: Yeah, the outside—all that welding—if it’s a MIG weld, then you’re just retooling the robotic path. You flash up your jig or fixture for that piece or change your end-of-arm tool so that it can pick the piece up. I’m oversimplifying, but looking at that video, I think, “Yeah, if I had the equipment I could put together a process for it,” and anything you don’t have, you just manually put it together. For something like welding, they probably pick certain plants, because obviously you don’t want someone having to do all that manually.

Given everything you’ve said, does it make sense to focus on automotive OEMs for ventilator production, rather than Tier 1 or Tier 2 suppliers?

Nathan: It has to be all of them: we need everyone. If you look at that Tesla video around 2:30, it looks like there’s a huge valve bank with a sensor block. You’d get a Tier 1 to make that block for you, but then you’d probably get the transmission plant or the OEM to assemble the valve bank. You need a supply chain for this: one company isn’t going to do it all. Even the control board; an OEM isn’t going to make that.

We’ve touched on it already, but do you think we should be concerned about the supply chain?

Nathan: I think there’s concern in the short term, but not in the middle or long term. Ultimately, I think every country is going to look to nationalize the production of life-saving medical equipment. Doug Ford, the premier of Ontario, basically said, “I never want to rely on a president, prime minister or anyone else for life-saving equipment again.” It’s a consequence of globalizing the supply chain, and in this instance that’s really hurt us. In the long run, it’s still going to be medical equipment suppliers making these ventilators, but some of the components might be sourced from non-traditional medical equipment manufacturers.

Image courtesy of GM Canada.

What about testing?

Luke: The way you develop a test plan for an automotive part involves several cycles. First, there’s design validation where you build the design out of prototype components to see if it makes sense functionally. From there, you go to production validation, where you use all the production intent equipment to develop a way to differentiate good parts from bad ones. You’ll get certain performance problems with the different variations that can happen in that process, so that gets carried into the actual manufacturing.

At that point, the question becomes: How do we catch these problems that are happening during the production validation stage? Then there’s all the statistics behind how you figure out which components are at risk, what failures are most risky, and how you test for them.

Does that mean automakers are starting from square one for testing ventilators?

Luke: They’ll have to design a full test program, but it’s not that complicated to do. You can whip up a test program in a couple of days, then it’s just a matter of creating the test equipment. You have to create fixtures and test profiles and electronics and then scale that from the development environment. And in development you’re doing one-offs or one or two per day, whereas in the production environment, there are some parts you have to test 100% and others you only test once per shift.

I don’t know exactly how it’s done in medical manufacturing, but it’s probably a similar combination of processes. They probably have more stringent expectations for final assembly, as well as a lot more redundancy and higher performance requirements.

Image courtesy of GM Canada.

So, the automakers will need to test to higher standards than they’re used to?

Luke: Not necessarily. The automotive industry faces the same thing with certain components that can’t be allowed to fail. Think of safety-critical systems like airbags: the requirements might be even more stringent than ventilators because it’s critical that an airbag works perfectly every time. If a ventilator stops working, there’s an opportunity to intervene and replace it; with an airbag, you’ve got one shot and it works or it doesn’t: it’s life or death.

Are there any other hurdles you can see in the short term?

Nathan: Well, you can retool an OEM, but automakers run a certain process; they have a procedure and a framework that they have to follow called the TS Standard. I don’t know what the equivalent is for medical equipment, but for automotive, everything is governed by this one specification.

So, it’s not as simple as an automaker saying, “I’m going to start making medical equipment,” because there’s a whole group of standards that they will have to adhere to. Even in the best of times, with a product that’s ready for production, it takes a year to get all the production processes proven out and done properly.

Even so, I think we’ll be better off because Ontario has a manufacturing supply chain that can support medical equipment production, and I think that will be beneficial for us. Ultimately, the people who make ventilators will continue making them; they’ll just source a lot more of their stuff from local Canadian suppliers as opposed to going overseas for it.

Share on social: