ETQ and Acerta close the loop on quality

In manufacturing, data is power. Yet, even with mountains of data, many companies struggle to turn it into actionable insights before quality issues spiral out of control. The answer lies in what’s known as a “closed-loop” system — an approach where feedback continuously informs and improves processes in real time.

But why is closed-loop quality so important? Because it ensures nothing falls through the cracks. Issues are identified, resolved, and then fed back into the system to prevent future occurrences. It’s a living, breathing cycle that keeps improving, adapting, and protecting your production line.

Now, Acerta and ETQ have taken this concept to the next level by partnering to create a predictive, closed-loop quality management system that integrates Acerta LinePulse and ETQ Reliance platforms. Together, these two technologies transform how manufacturers approach quality control.

How the closed-loop system works

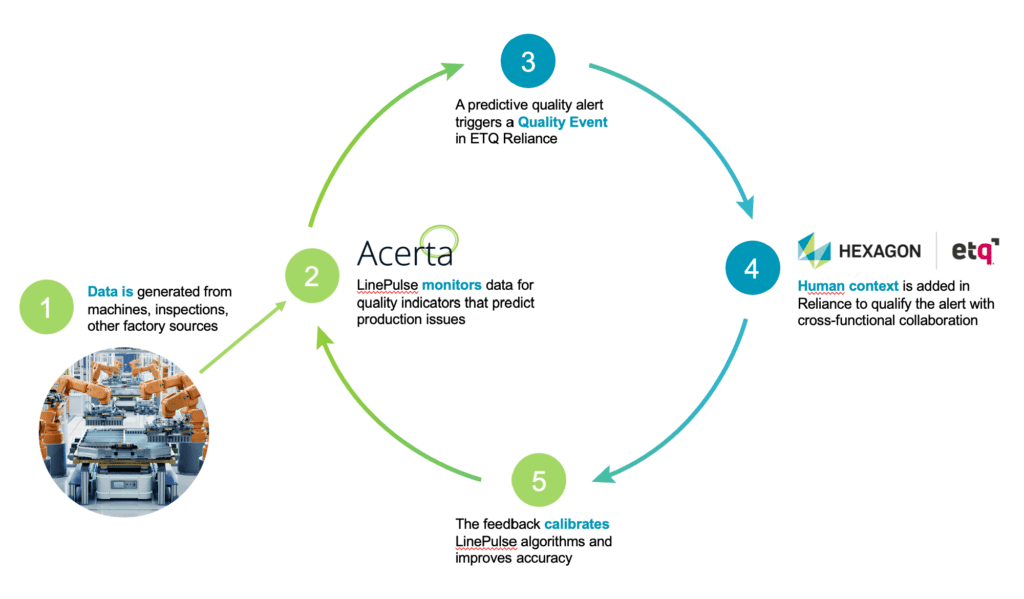

Think of it like this: Acerta LinePulse is your early warning system. It analyzes data from the shop floor in real time, using machine learning to spot patterns that might indicate a potential defect or production issue. Once an issue is detected, LinePulse immediately sends an alert to ETQ Reliance, a powerful quality management system (QMS). Reliance takes that alert, tracks it through customizable workflows, and organizes the necessary actions to resolve it.

And here’s where the magic happens: once the issue is resolved, feedback from the resolution is sent back into the Acerta LinePulse system, improving the algorithm’s ability to predict and catch similar issues in the future. The more data LinePulse gets, the smarter it becomes, and the more efficiently your manufacturing line operates.

As Greta Cutulenco, CEO of Acerta, explains: “Coupled with Acerta’s long-standing history of providing AI solutions to large automotive manufacturers, together we will now deliver insights to manufacturers that help them predict and resolve issues with real-time analysis of their shop-floor data, and expert feedback from ETQ Reliance users.”

Why this matters to manufacturers

Manufacturers today face constant pressure to innovate, ensure operational efficiency, and avoid the catastrophic costs of product recalls. In fact, according to a recent survey, 73% of manufacturers have experienced a product recall in the last five years. The stakes are high, and traditional quality control systems, which often react to issues only after they’ve occurred, are no longer enough.

A closed-loop system like the one created by Acerta and ETQ keeps you ahead of the curve by identifying problems before they can impact your production line. As Vick Vaishnavi, CEO of ETQ, put it: “The ETQ Reliance Predictive Quality solution combines AI technology and expert human knowledge to help identify production problems sooner and resolve them faster to avoid costly, brand-damaging recalls and other quality issues.”

The cost of poor quality is immense, from wasted materials and rework to expensive product recalls and lost customer trust. For manufacturers, controlling these costs is one of the few levers they have to increase productivity without sacrificing output. A predictive, closed-loop quality system allows manufacturers to prevent defects early, reduce scrap, and avoid rework, all of which lead to significant savings. By minimizing waste and improving efficiency, manufacturers can boost productivity and free up resources to focus on innovation and growth.

A partnership between human experts and intelligent machines

Quantitative data from the shop floor analyzed by LinePulse in real time gives quality, process, and manufacturing engineers and managers the important insights they need to quickly inform critical decisions. The integration with ETQ Reliance adds qualitative data — the human expertise and context needed to add a deeper understanding to the machine learning analysis, and teach it to generate more accurate predictions over time.

The ETQ and Acerta partnership isn’t just an effective product that improves productivity and reduces scrap, but the innovation marks a maturation of the relationship between AI and manufacturers. It is a true a collaboration between human experts and intelligent machines.

In the world of manufacturing, that’s a game-changer.

Share on social: