Last updated on March 19th, 2025

Case Study

Automating end-of-line tests with AI

Objectives

- Improve EOL testing for electric power steering systems to catch more defects and reduce warranties in the field

- Identify failing units with 0% false negative rate and <1% false positive rate

Challenge

- Client required performance comparable or better than human inspectors

- Models trained exclusively on data from normal (i.e., non-defective) systems

Key Results

100%

Of systems most likely to fail EOL testing identified

<1%

False positive rate

Background

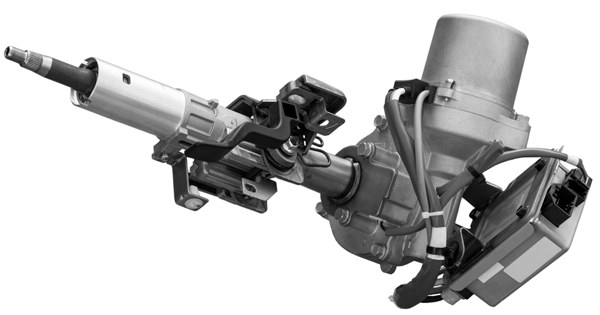

A leading Tier-1 supplier of driveline components was looking to improve its end-of-line (EOL) testing for electric power steering systems. The client’s goals were to reduce warranties by identifying more defective systems and to replace their manual EOL test with an automated solution. The existing end of line testing regime used data gathered from four vibration sensors over the course of 8 tests, for a total of 96 signals per unit tested. The results were then manually evaluated by a team of engineers.

The Problem

The client requested a machine learning model that would perform as well or better than its human EOL testers, which meant a false negative rate of 0% and a false positive rate of <1%. Acerta’s training dataset consisted of roughly 700 electric power steering systems, none of which failed end of line testing. Our data scientists used 5-fold and 10-fold cross-validation plus 27 failed units to test their classification model.

Solution Process

Acerta’s team began by gathering information about the client’s manufacturing and data collection process, which informed our intelligent feature engineering. The client had already been applying signal processing to its EOL data, but Acerta’s data scientists augmented this approach with our machine learning model.

Moreover, because the project involved analyzing vibration data (one of Acerta’s specialities), our data scientists were able to leverage insights from another project, that used vibrations to predict failures in gearboxes. Consequently, Acerta was able to complete the project more quickly by using machine learning model types that had proven to be most successful at this task and reconfiguring them, rather than starting from a blank slate.

Results

This demonstrated Acerta’s facility with vibration data as well as the continuous improvement of our machine learning model: our data scientists were able to take the success in one application—using vibration data to predict gearbox failures—and apply it to a different application: using NVH data to predict electric power steering system failures.

Acerta succeeded in identifying electric power steering systems most likely to fail end of line testing with almost 100% accuracy. Acerta achieved the client’s objective of a 0% false negative rate and <1% false positive rate, resulting in an automated EOL test that performed comparably to (or possibly even better than) the client’s human testers.