How the industrial revolutions shaped automotive

Last updated on February 5th, 2024

Can you imagine what your life would look like without any machines working for you?

At one point that was the reality for everyone on Earth. Fueled by the animals we raised, the plants we grew, and the wood we burnt, all production came from the sweat of one’s brow.

The hardships of this simple lifestyle sparked the need for new technologies, with each innovation leading to countless others. As a result, human civilization has undergone multiple revolutionary transformations to get to where it is today.

“Technological change rarely advances smoothly. It advances in pulses. In revolutions. This pattern holds true in virtually every field, and each pulse opens the door to new innovations that revolutionize industries and, sometimes, society itself.”

Mary Barra, CEO of GM

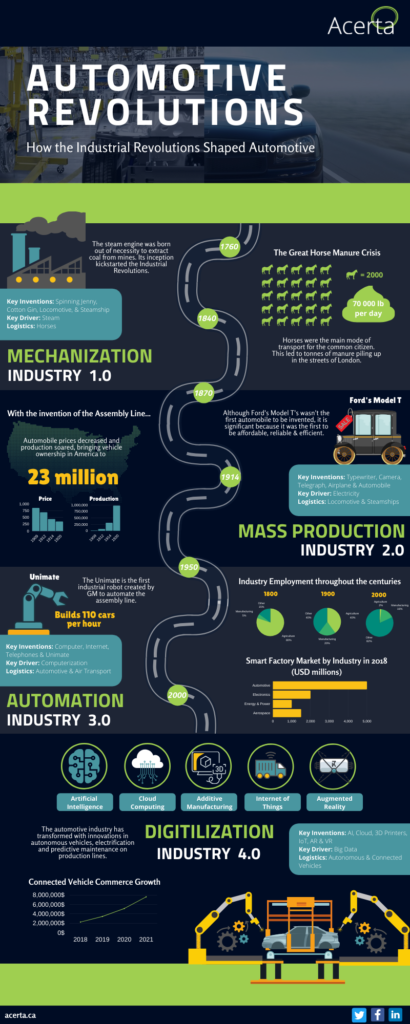

Specifically, we’re talking about the industrial revolutions, and yes, that’s revolutions with an “s”. There have been three industrial revolutions over the last several centuries, each one fundamentally changing the ways we work, the tools we use, and the products of our labour.

Broadly speaking, we can define the revolutions in terms of a few key concepts and technologies:

- The First Industrial Revolution (1760-1840): Mechanization & Steam Power

- The Second Industrial Revolution (1870-1914): Mass Production & Electricity

- The Third Industrial Revolution(1950-2000): Automation and Computerization

And right now it’s happening again, for a fourth time.

Also known as “Industry 4.0” this quintessential buzzword refers to the fourth industrial revolution that’s happening all around us and includes cutting-edge technologies like additive manufacturing, artificial intelligence, augmented and virtual reality, and the Internet of Things.

These kinds of paradigm shifts can be difficult to appreciate if looked at all at once, so (since it’s our business) let’s take a look at the industrial revolutions through the lens of one industry in particular: automotive.

To begin, we need to travel back in time to just before the inception of the automotive industry in order to see how the First Industrial Revolution laid its foundations.

It all started around 1750 in Great Britain…

Mechanization & The Dawn of Manufacturing (1760-1840)

Right from the start, industrial production was about the most efficient use of resources. First it was coal: extracting it via mining was hampered by the need to pump water out of mines to gain better access to this natural resource.

Thus, the steam engine was born.

Soon the world became enchanted by the wonders of steam power, leading to a series of inventions that began the mechanization of human labor: the spinning jenny, the cotton gin, and the first modern machine tools are but a few examples.

From the perspective of supply chains, steam power enabled goods to be shipped over land and sea at the fastest rates in history thanks to locomotives and steamships.

Despite these innovations, horses remained the primary means of both power and mobility, leading to “The Great Horse Manure Crisis of 1894” with manure piling up by the tonne all over London.

By the mid 19th century, the tell-tale signs of an industrial society – smoke rising from factories, growing cities and workers being regulated by the clock rather than the sun – were becoming commonplace across Europe, but there was a growing need for a convenient mode of transportation.

While Britain was busy demonstrating their capabilities of being the world’s leading manufacturer of machinery, there were rumblings abroad of a new type of engine that was faster, cheaper, and more efficient.

Assembly Lines & Automobiles (1870 -1914)

Amidst the inventions of the typewriter, camera, telephone and airplane, the second industrial revolution marked the world’s entrance into the age of automotive transformation.

While electricity was replacing steam as the primary source of industrial power, several innovators and inventors helped shape this momentous stride in history. In 1861 Nicholaus Otto created the first practical gasoline powered engine that made the steam engine old news. Carl Benz followed shortly after with the first design of the automobile. Last but not least there was Henry Ford and the development of the assembly line.

By the early 20th century, hundreds of car manufacturers were popping up in the United States and Europe. But there was one problem: the cars were too expensive.

"If I had asked people what they wanted, they would have said faster horses."

Henry Ford, Founder of the Ford Motor Company

They say the best inventions are created out of necessity. In this case, it was the necessity for an affordable, reliable and efficient mode of transportation that would be widely accessible to the public.

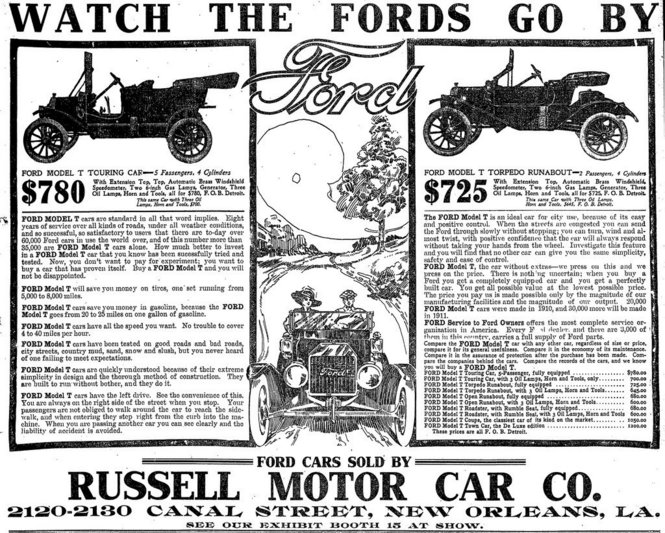

Henry Ford dreamed up a machine that could accomplish just this. The Model T from Ford Motor Company was the first mobility solution that brought car ownership within reach of the average American, making it easily the most significant invention of its era.

But he didn’t stop there.

With continuous improvement on his mind, Ford was continuously perfecting his assembly lines to advance the mass production of automobiles.

By lowering labour costs and improving efficiency, the Model T’s price was drastically reduced from $850 in 1908 to $300 in 1924. What was once a luxury item could now be bought by the majority of the working class.

America was forever changed through this singular development. The demand for automobiles drove subsequent demand for glass, steel and rubber, further expanding domestic and international supply chains. The need for interchangeable parts and semi-finished products led to the refinement of factories into what most people picture them as today.

And soon the world started to follow suit.

The Digital Revolution (1950 - 2000)

If you’re reading this blogpost, you’re utilizing the core of the 3rd industrial revolution right in this moment: the digital computer. Due to advancements made in technology during World War II, the world was poised to embrace a new age of digitalization.

With the creation of semiconductors – transistor-based electronics, computers, and telecommunication allowed us to move from an analog to a digital world.

But what did all of this mean for the automotive industry?

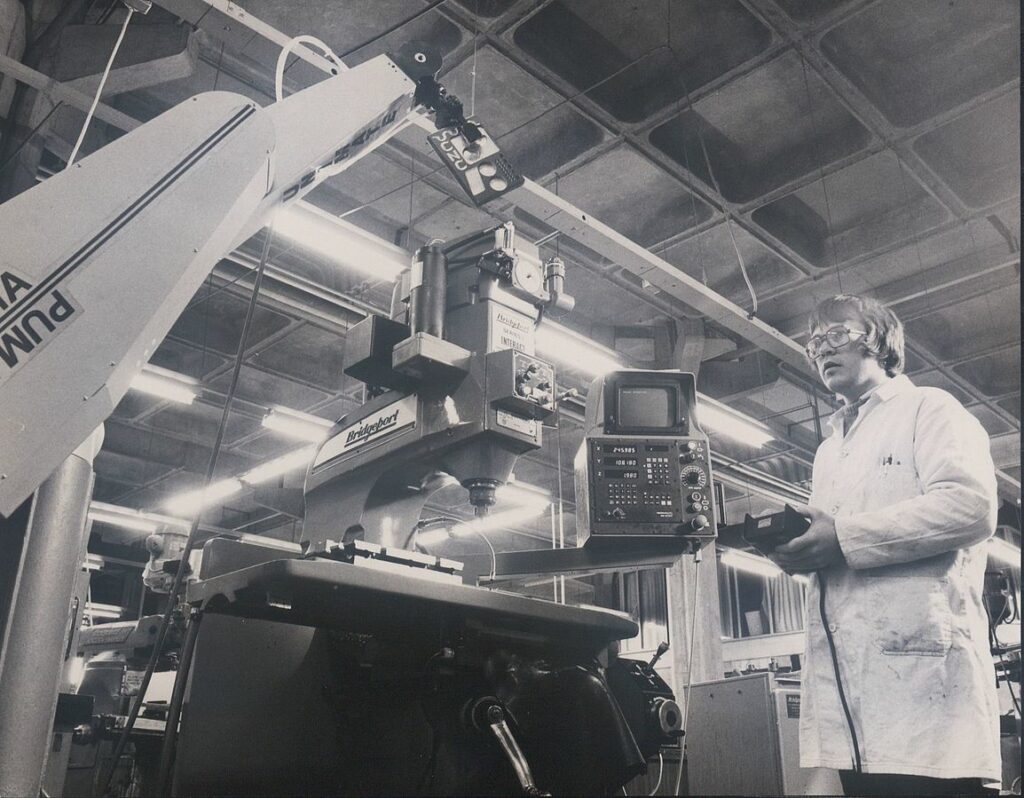

For one, it allowed companies to start thinking about automation in the assembly line. Notably, GM developed the first industrial robot to automate metalworking and welding processes: the Unimate, thereby streamlining manufacturing operations beyond even Henry Ford’s wildest dreams.

More and more cars and trucks were on the road with each passing year.

Competition emerged for the “Big Three” automakers (GM, Ford and Fiat Chrysler) from post-War Europe and Japan – which rapidly became the new leading automotive producing nation. Globalization opened the door to vehicle manufacturing at a fraction of the cost.

Engine power grew, vehicle speeds soared, designs became pieces of art, and prices began to drop.

Although “faster” and “cheaper” were on everybody’s minds, we also began to consider safety and the environment, with the addition of seatbelts and the invention of hybrid cars on the horizon; making cars not only sleek but also sustainable.

Industry 4.0 (2011 - Present Day)

Unbuckle your seatbelts and step out of the time machine; we’re back in the 21st century.

Welcome to the fourth industrial revolution.

Although the definitions for Industry 4.0 vary, it revolves predominantly around 5 key technological feats: additive manufacturing (3D printing), augmented reality (AR), Internet of Things (IoT), Artificial Intelligence (AI) and the Cloud – also known as buzzword palooza.

These technologies are driving the innovative minds of today. Improving human life in a multitude of facets.

Everything we could and couldn’t have dreamed of has become a reality in the automotive industry. From autonomous vehicles, electrification and predictive maintenance in production lines to the simple pleasure like heated seats (my personal favourite), bluetooth connectivity and cruise control.

Granted, we may not be flying our cars into the Whomping Willow tree anytime soon, but there’s plenty of automotive “magic” still to come.

"The automotive industry has entered an era of profound transformation, of the kind that happens only once every hundred years"

Akio Toyoda, President of Toyota Motor Corporation

Here at Acerta we’re excited to be taking this journey with you! In the next installment, we’ll take a closer look at automotive technologies in the fourth industrial revolution. But for now, check out our infographic below!

Share on social: