ML/AI-enabled predictive modeling delivers precise predictions

Last updated on June 19th, 2023

Accurate predictions can have a huge impact on manufacturing. They can help precision manufacturers increase throughput, reduce machine downtime, improve product quality, develop data-driven action plans, and much more.

Modern predictive modeling is a statistical technique that leverages machine learning (ML) and artificial intelligence (AI) to analyze historical and current data to generate a model that accurately predicts outcomes. An effective predictive ML/AI modeling platform can empower data scientists and/or production managers with the actionable insights they need to develop solutions that can reduce failure rates and rework — but there are challenges.

Three challenges in predictive modeling

1. Definitions and timelines

Predictions have a distinct meaning to different professionals. Data scientists use mathematical formulas and other input parameters to anticipate a result, and if their calculations are correct, they call it an accurate prediction. The typical data scientist works to a schedule that’s measured in days, if not weeks.

On the other hand, production managers measure their schedules in minutes, so time is critical. A prediction is something that hasn’t happened yet, which is useless to them. They need predictive models that use real-time data to deliver insights they can act on immediately, to ensure continued product throughput and quality.

2. Data Leakages

Data scientists are very wary of data leakages. When they collect a lot of information on a particular part and analyze it extensively, they worry they could expose sensitive data to unauthorized outside users. Even shipping data can be considered sensitive, such as shipping a part based on its quality information.

For example, a predictive model could calculate that the highest quality parts should be shipped to a particular country with higher quality-acceptance standards, compared to the quality of parts that will be satisfactory elsewhere. Obviously, this is information that manufacturers would prefer to keep in-house.

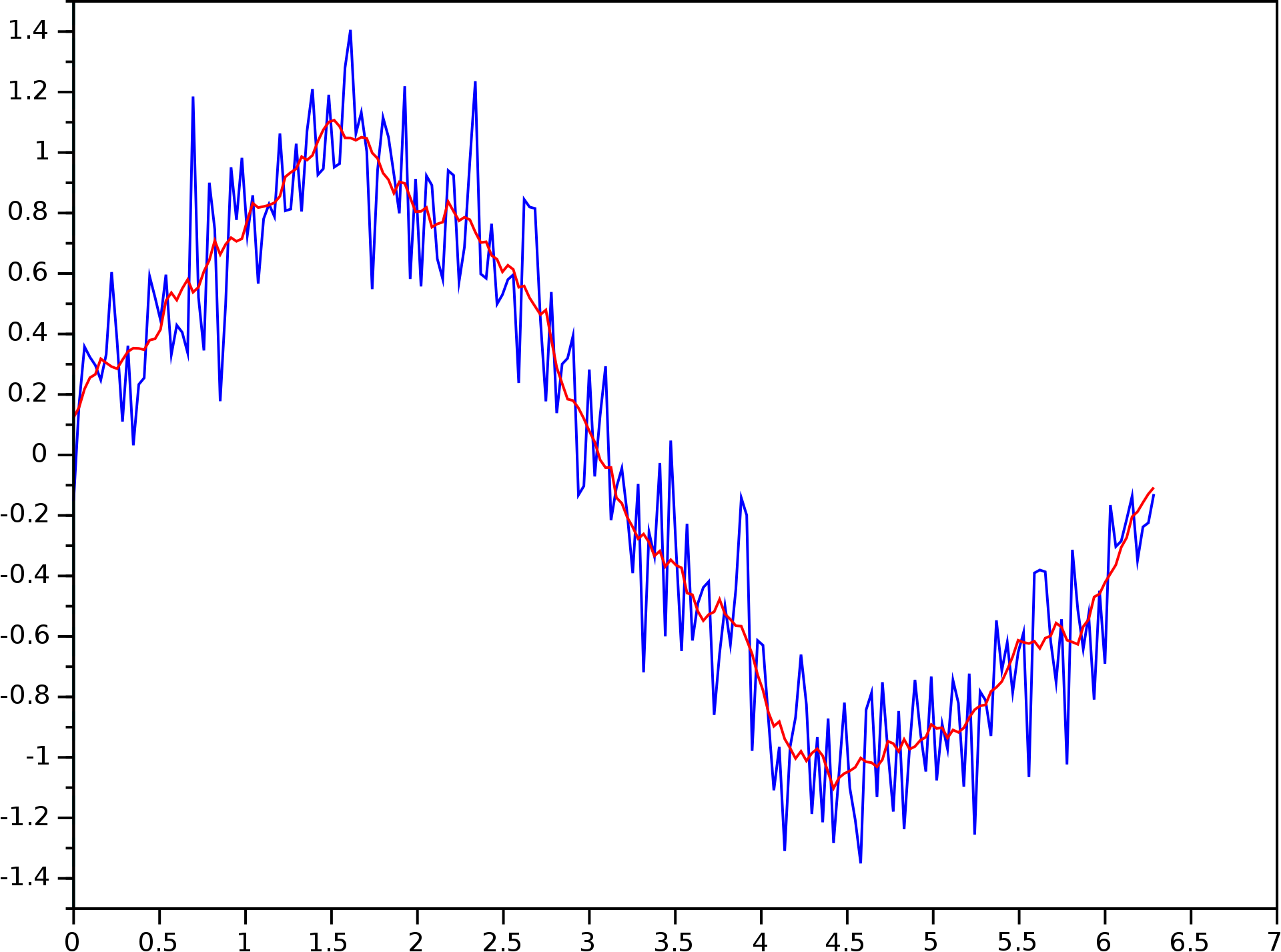

3. Moving Averages

A moving average is a technique used to gain insight into production data. It is compiled from an average of a subset of numbers, such as information collected from the production line. A moving average is useful for forecasting long-term trends. However, the technique is complex, and delays while collecting data could leave your data scientists and/or production managers with insufficient time to perform the mathematical calculations needed to deliver a useful prediction.

Overcoming predictive modeling obstacles

A good predictive ML/AI solution can address the challenges above and deliver actionable insights. By using unattended AI to continuously collect data, while an automated ML model runs in the background, the solution can analyze data as it comes in, to generate accurate real-time predictions.

For example, a predictive model using ML/AI can scan multiple signals from the production line to detect shifts in patterns, better known as pattern drift. This data can be used to make accurate predictions about the ongoing operations of the production line and/or changes to product quality, which production managers can act on.

Additional benefits of using an ML/AI predictive solution

ML/AI can be used for more than just extracting actionable insights from your data. It can also identify opportunities and help you to develop data-driven action plans to improve manufacturing throughput, product quality and even user safety.

For example, Acerta is partnering with Nissan to develop an advanced analytics platform of customized ML models for the Nissan Research Center. Acerta’s predictive maintenance technology will enable Nissan vehicle users to receive notifications of maintenance needs ahead of time, saving them money and improving vehicle safety.

Ready to make better predictions?

Acerta’s LinePulse solution can provide a digital view of your entire production process, display timely manufacturing information at-a-glance, deliver accurate predictions, and evolve as your production line changes. Our ML/AI-powered LinePulse software and Acerta Professional services enable precision manufacturers to make the right decisions fast, optimize production, and improve product quality.

Want to translate complex product data into actionable insights? Get in touch.

Share on social: